Manufacturing Consulting Services

About US

At Atlantic Manufacturing Solutions, we offer a comprehensive range of manufacturing consulting services to help businesses optimize their operations, improve efficiency, and drive growth. Our team of experienced engineers and consultants works closely with clients to identify challenges, develop innovative solutions, and implement strategies that deliver tangible results. Whether you're looking to streamline your production processes, enhance product quality, or expand your manufacturing capabilities, we have the expertise and resources to help you achieve your goals.

The first and foundational step in our process involves a deep dive into understanding the specific needs and requirements of our clients. This stage is critical for establishing a clear, comprehensive brief that outlines the project's objectives, constraints, and criteria for success. Our team at AMS collaborates closely with clients to gather all necessary information, ensuring that every aspect of the project is meticulously defined. This thorough understanding serves as the bedrock upon which all subsequent design and engineering decisions are made, guaranteeing solutions that are not only innovative but also perfectly aligned with our clients' goals.

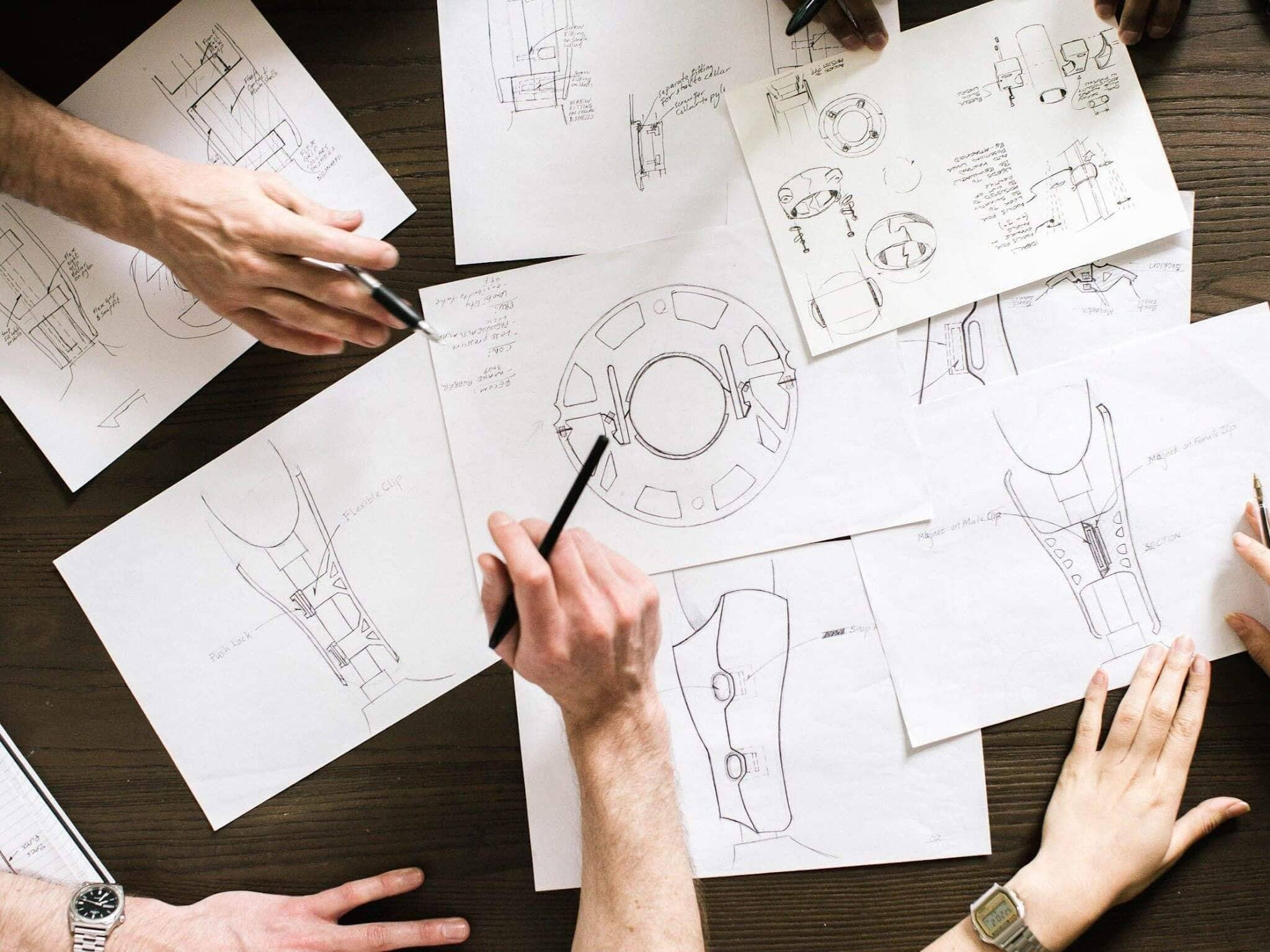

Following the clear definition of requirements, our team transitions into the concept generation phase. Here, creativity meets engineering prowess as we brainstorm a wide range of solutions. Leveraging our expertise in various engineering disciplines, we explore multiple ideas, considering different approaches and technologies that could be used to meet the project's objectives. This stage is characterized by open-mindedness and innovation, with the aim of producing a diverse set of concepts that can be evaluated for feasibility, performance, and impact. It's a collaborative and dynamic process that taps into the collective knowledge and creativity of our team to pave the way for groundbreaking solutions.

Once a broad spectrum of concepts has been developed, the down select phase focuses on evaluating these ideas against the project's defined requirements and constraints. This critical analysis involves rigorous assessment criteria, including technical feasibility, cost-effectiveness, scalability, and sustainability, among others. The goal is to narrow down the options to the most promising concepts that offer the best balance of innovation, practicality, and potential for success. This stage ensures that resources are concentrated on developing solutions with the highest likelihood of meeting and exceeding our clients' expectations.

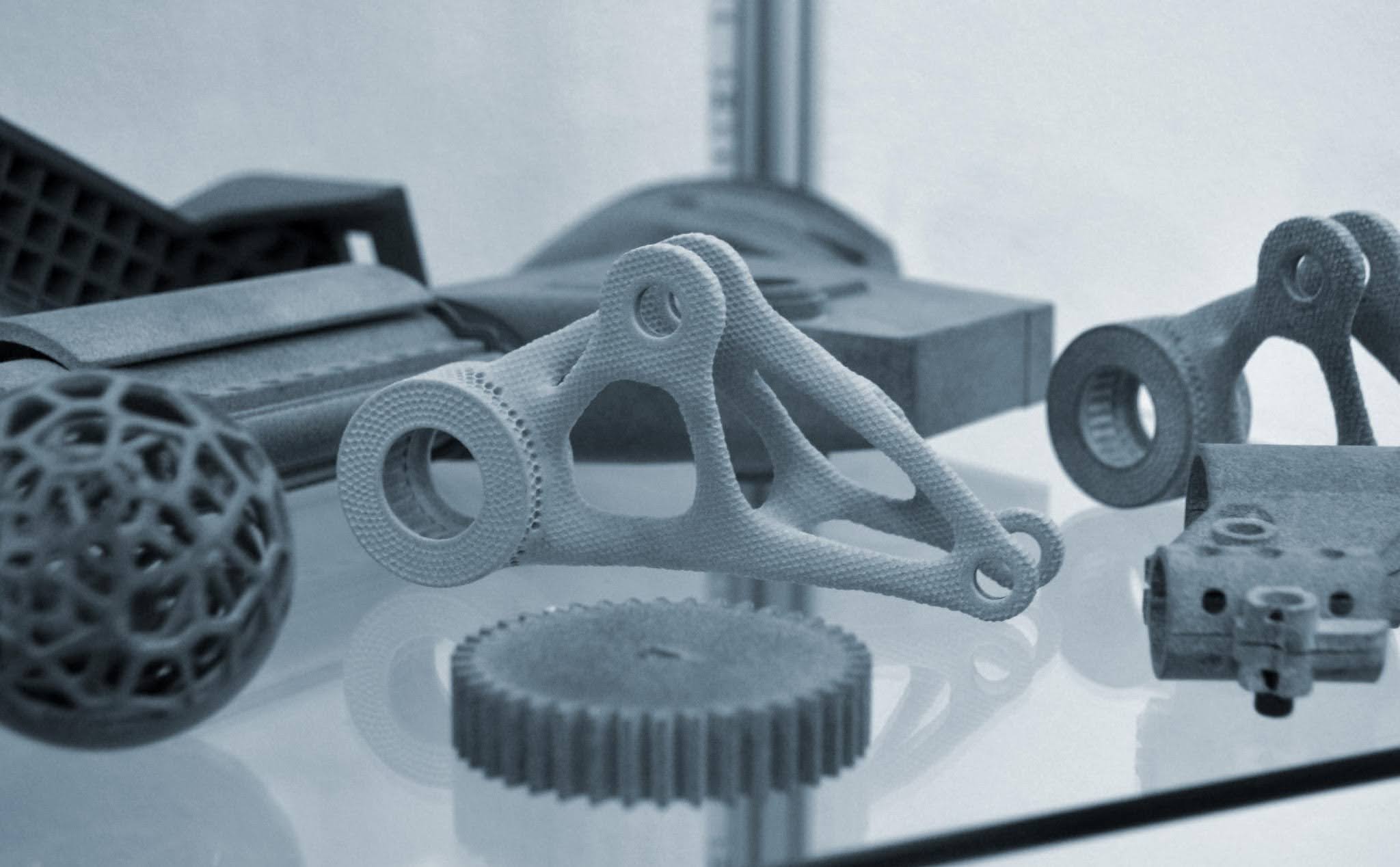

With the most viable concepts selected, the next step is to bring these ideas to life through prototyping. This phase is all about translating theoretical designs into tangible models that can be tested and evaluated. Prototyping is crucial for identifying any design flaws, assessing the functionality of the product, and gathering feedback for further refinement. It allows for a hands-on approach to problem-solving and innovation, enabling our team at AMS to iterate quickly and efficiently. By the end of this stage, we have a working prototype that demonstrates the feasibility and potential of the proposed solution.

Following prototyping, the refinement phase focuses on optimizing the design based on feedback and test results. This stage involves making adjustments to improve performance, enhance user experience, reduce costs, or address any other identified issues. Our team works meticulously to fine-tune every aspect of the product, ensuring that it not only meets but surpasses the initial requirements. This process of continuous improvement is guided by a commitment to excellence and a deep understanding of engineering principles, ensuring that the final design is robust, efficient, and ready for manufacturing.

The final step in our process is the transition from refined prototypes to full-scale production. This phase is where our engineering solutions are realized as tangible products, ready for the market. Our manufacturing process is characterized by a strict adherence to quality standards, efficiency, and scalability. We work closely with trusted manufacturing partners to ensure that each product is produced to our exact specifications, using the most suitable materials and technologies. Throughout this stage, we maintain a focus on sustainability and cost-effectiveness, ensuring that our solutions are not only innovative but also accessible and responsible.

We are a team of experienced engineers and designers who are passionate about bringing your product to life. We offer a wide range of services to help you with all your metal fabrication needs.

We are here to help you with all your metal fabrication needs. Contact us today to get a free quote.